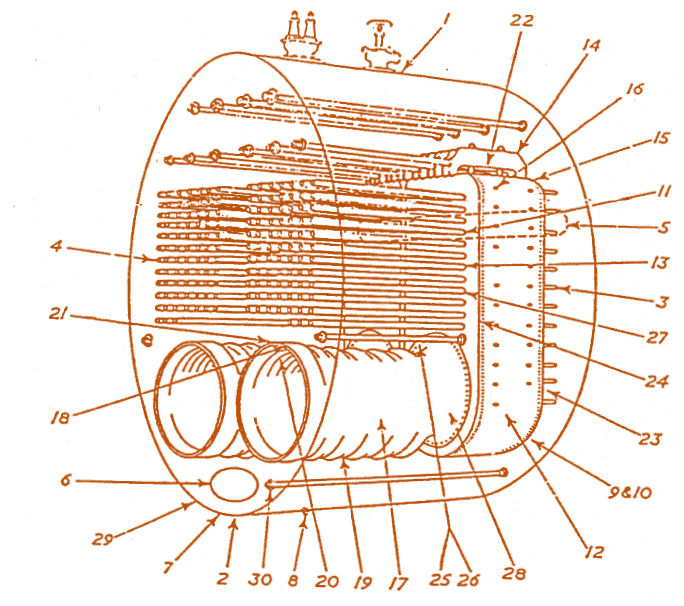

40 fire tube boiler diagram

This week we take a look at an American Industrial Icon. The Firetube Boiler. Plants have relied on these workhorses for decades for Steam and Hot water pr... Fire tube boiler—a device that passes hot combustion gases through the tubes to heat water on the shell side, p. 298. Igniter—a device (similar to a spark plug) that automatically ignites the flammable air and fuel mixture at the tip of the burner, p. 292.

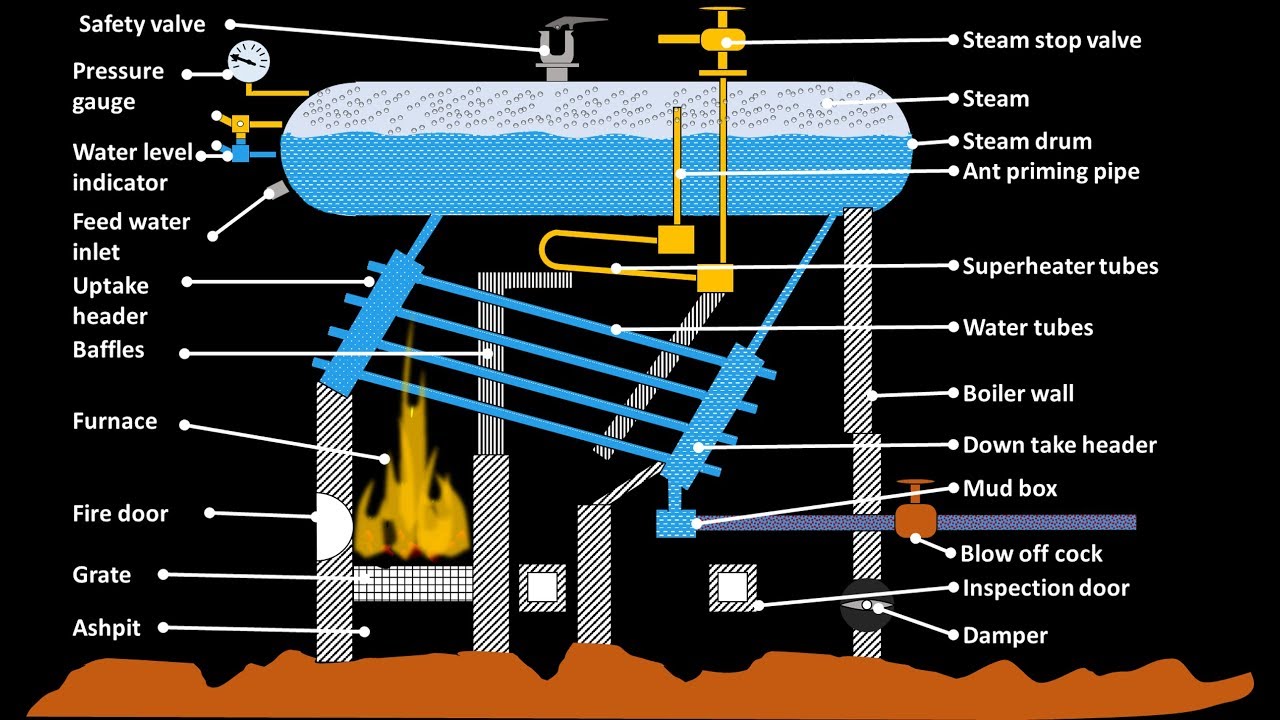

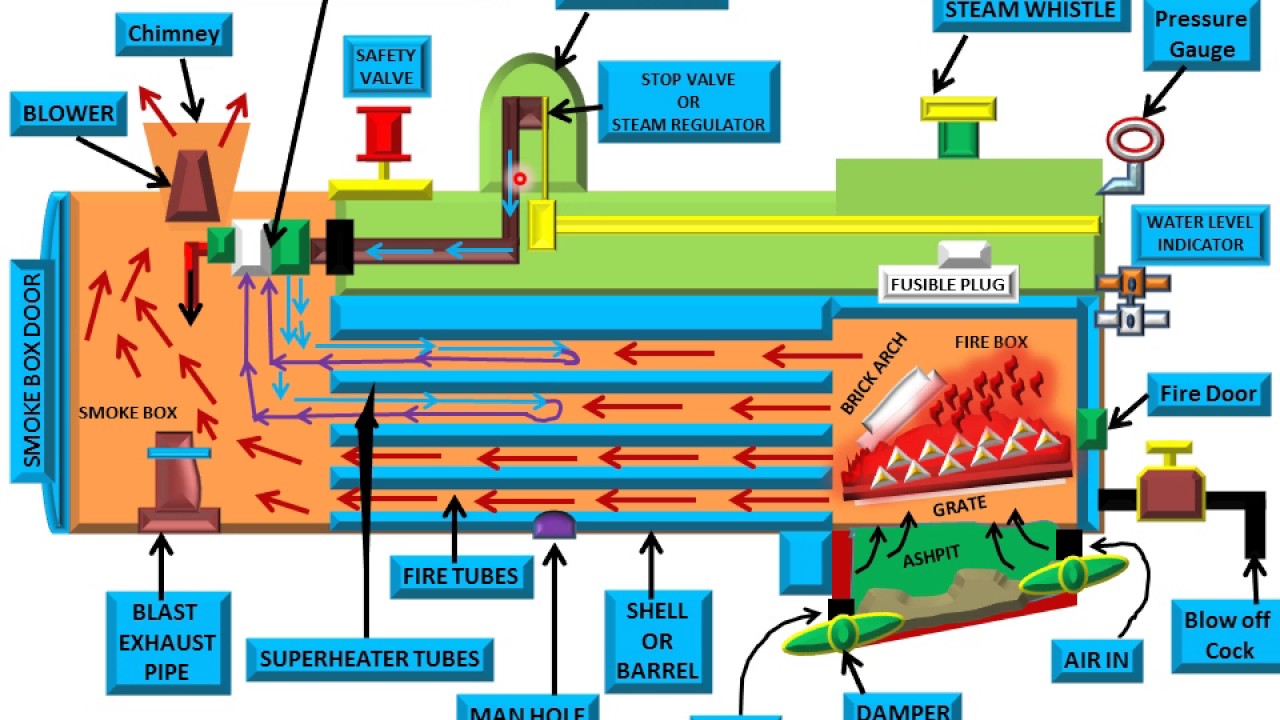

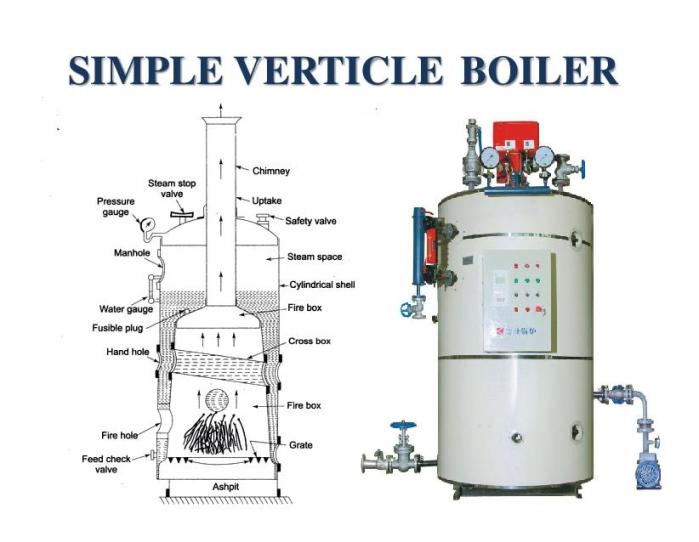

Fire Tube Boiler Diagram. These boilers include a water level indicator; a pressure gauge, steam stop tap security tap, & a manhole like mountings for providing security as well as simplicity of working. The Fuel burns on the grate of the firebox in the boiler and the resultant hot-flue gases are permitted to flow in the region of cross tubes.

Fire tube boiler diagram

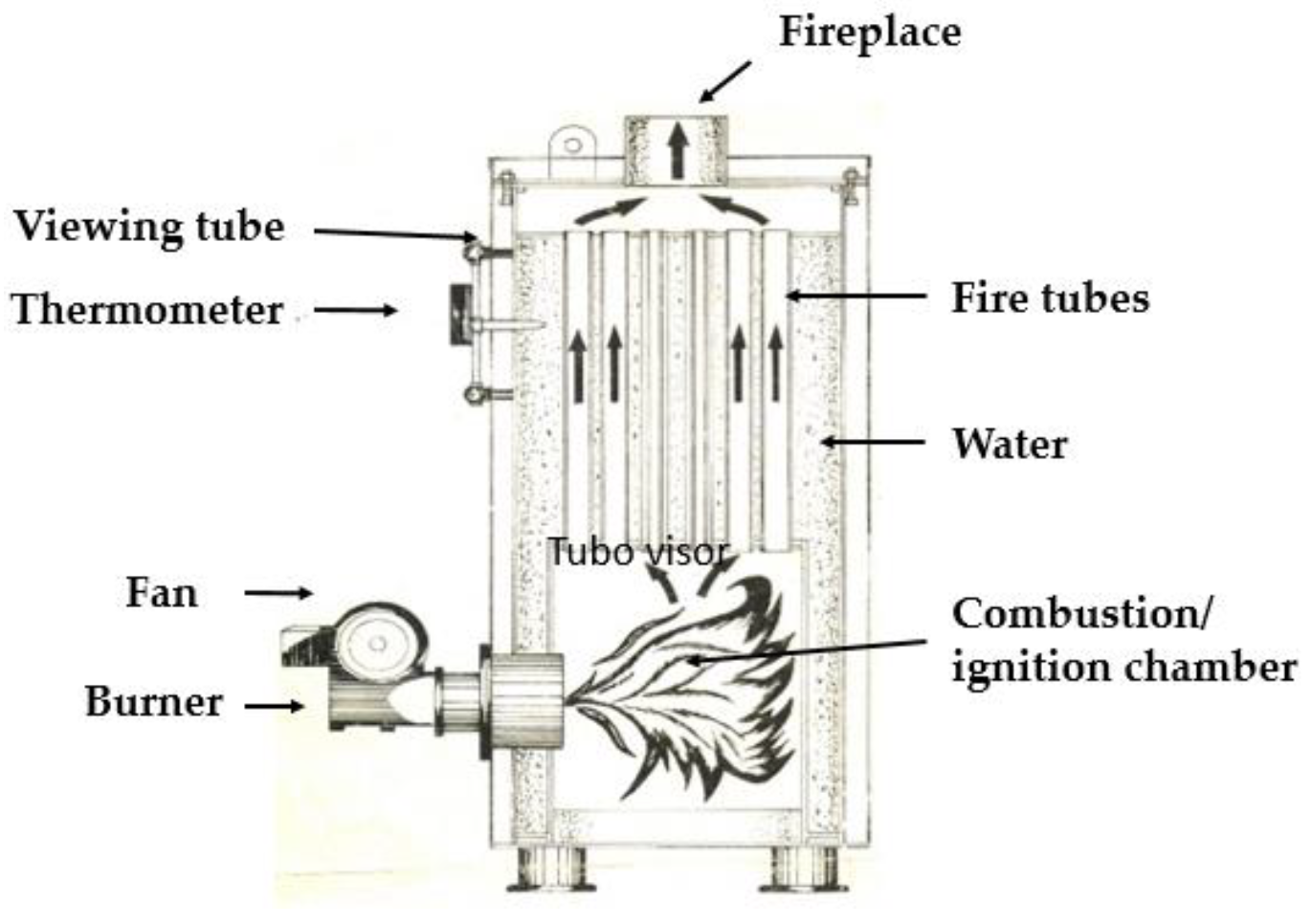

750-94 (revised 2009) Model CB, CB-LE Packaged Boiler Manual i Model CB, CB-LE Packaged Boiler 750-94 Table of Contents CHAPTER 1 Basics of Firetube Operation 1-1 1.1 — Introduction 1-1 1.2 — The Boiler 1-4 1.3 — Construction 1-5 1.4 — Steam Controls (All Fuels) 1-6 1.4.1 — Operating Limit Pressure Control 1-6 1.4.2 — High Limit Pressure Control 1-7 1.4.3 — Modulating Pressure ... The shell of this type of boiler is arranged in the vertical direction that has multi tubes. These multi tubes arranged in vertical and the high ... Fire tube boiler is one of the most basic types of boiler and the design is also very old. It was popular in 18 th century. It was mainly used for steam locomotive engines. Operation of Fire Tube Boiler. Operation of fire tube boiler is as simple as its construction. In fire tube boiler, the fuel is burnt inside a furnace.The hot gases produced in the furnace then passes through the fire tubes.

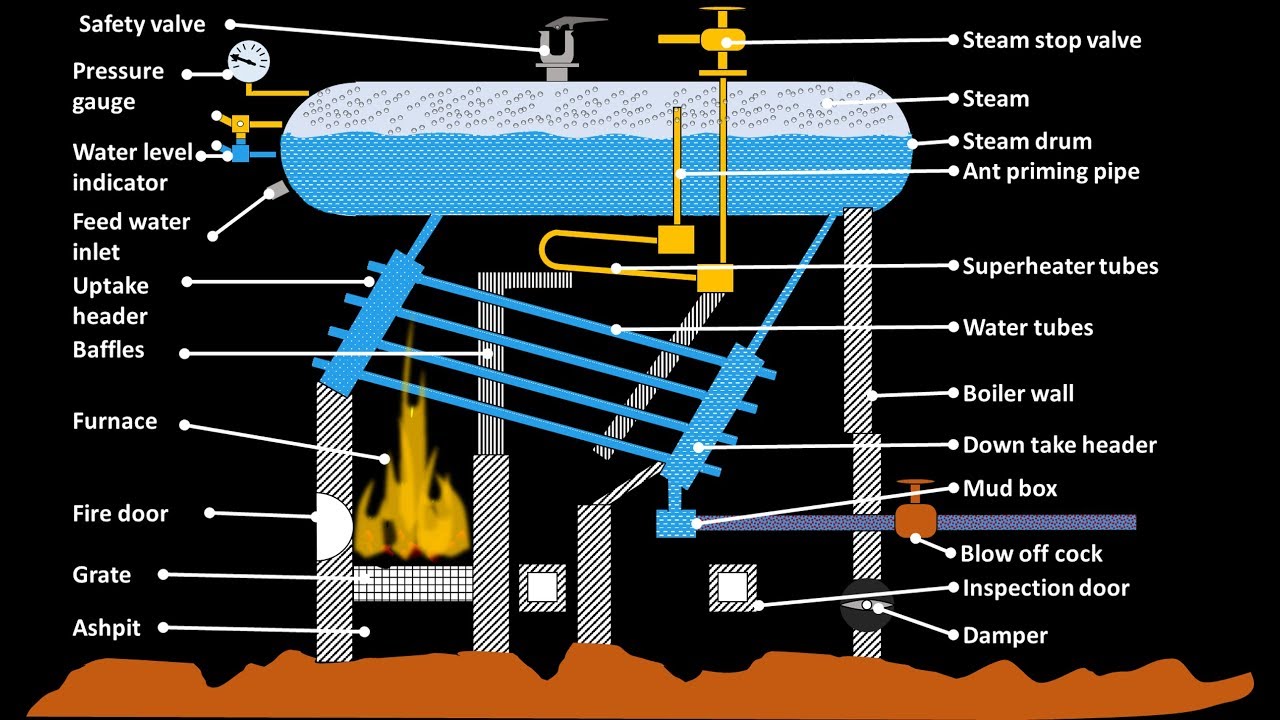

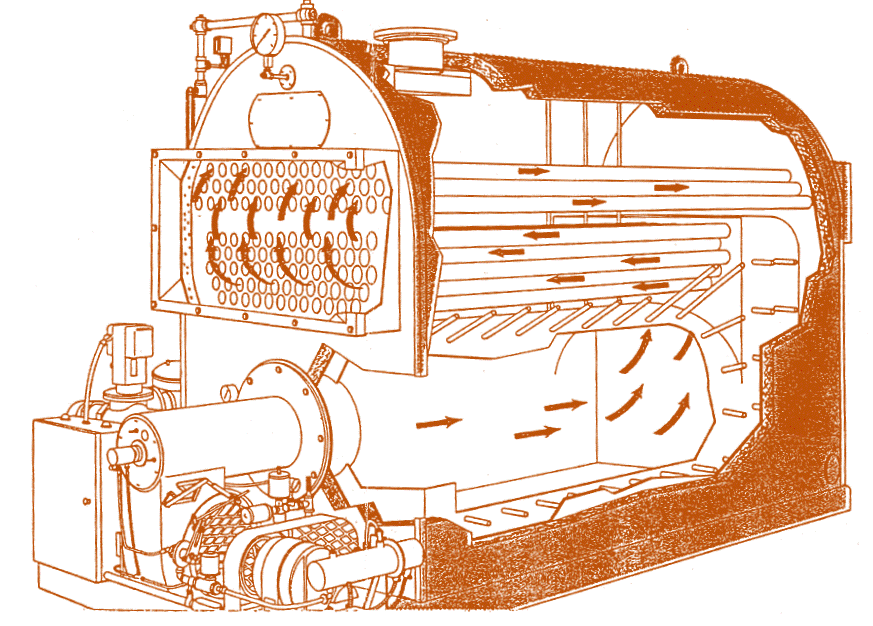

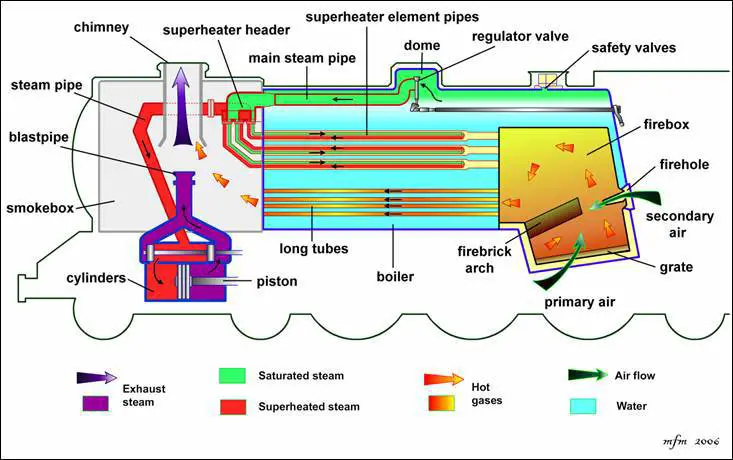

Fire tube boiler diagram. Fire tube boilers are useful for small demands of steam and water tube boilers are useful for industrial level usage. To cut short the main purpose of boiler is to boil a liquid mostly the water in order to generate the steam for serving the purpose of heating a building or running an equipment through pressurized steam or pressurized water. The grate for hand fired boilers consists of straight cast iron fire-bars which form a square in the centre, the area then left being filled in with pieces of design similar to the bars. The ashpit is formed by the extension of the boiler shell and is fitted with a portable cover. Construction of Scotch Marine Fire-Tube Boiler: Firetube steam boilers are composed of a cylindrical hull filled with thermal insulation in which a series of tubes are contained. Hot air from a burner is passed from a furnace in the 1st pass to a series of tubes in the 2nd pass, then to a series of tubes in the 3rd pass. It is recommended to name the SVG file "Locomotive fire tube boiler schematic.svg" – then the template Vector version available (or Vva) does not need the ...

steam boiler process flow diagram. 2016-12-15 Jenny Wu 0. ... The so-called fire-tube boiler is a gas produced by combustion of fuel in the fire extinguishers or smoke too Header Pipe, fire extinguishers or smoke on the external water pipes, vapor or steam mixture is heated. FIRE TUBE BOILER. Hot flue gases flow inside tubes that are submerged in water within a shell. • Pressures up to about 10 bar Ever wonder how your boiler is creating steam? Today on the Boiling Point, Ritchie talks with Steven Taylor about how a firetube steam boiler works. Boiler's... Most of the fire tube boilers now come in a complete package.The main parts of the package are : oil burners. fuel pump. forced draft fan. feed pump. automatic control system. Boiler mountings. The most basic type of a package boiler is single passage three pass design. One such boiler is shown in the figure.

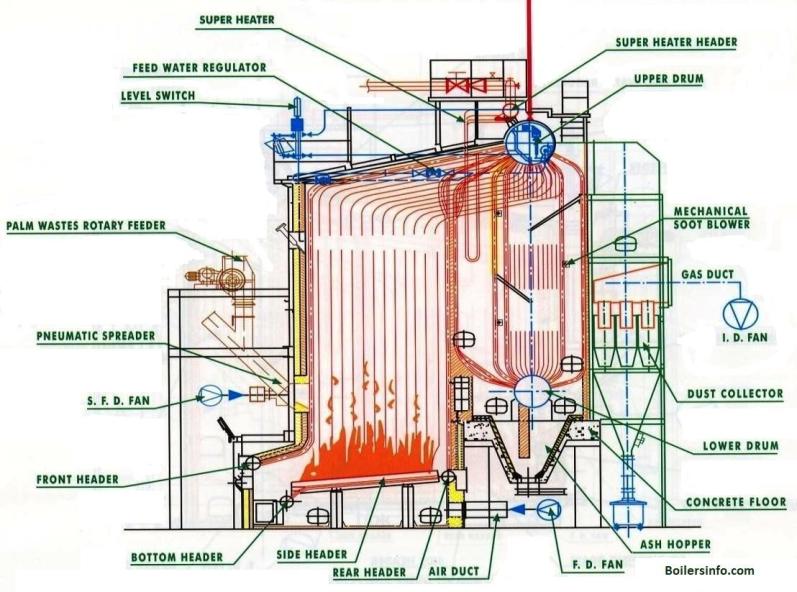

The fire-tube boiler developed as the third of the four major historical types of boilers: low-pressure tank or "haystack" boilers, flued boilers with one or two large flues, fire-tube boilers with many small tubes, and high-pressure water-tube boilers. Their advantage over flued boilers with a single large flue is that the many small tubes offer a far greater heating surface area for the ... SD235239-01 Fire Tube Boiler. SD235239-02 Access Platform Arrangement for Fire Tube Boiler. SD235239-03 Natural Gas and Liquefied Petroleum Gas Burner and Igniter Fuel Standard Piping Diagram. SD235239-04 No. 2 Burner Fuel Oil Systems Standard Piping Diagram. SD232111-07 Boiler Feedwater Pumps Flow Diagram. SD232111-08 Boiler Flow Diagram. 5. The fuel-air mixture enters the furnace through the burner 1 under the pressure of 200 PA which allows overcoming of the aerodynamic resistance of the gas path ... The water tube boiler diagram is shown below, and these two drums are associated via two tubes such as downcomer and riser. At first, the water is supplied into the steam type drum with the help of a water pump. Whenever the fuel is burned, then hot gases will be generated that are permitted to supply in the shell part of the boiler.

Babcock And Wilcox Boiler Working Animation Simple Diagram Construction Explained Water Tube Boiler Youtube

How Boiler Work? Boiler Operation. Course Objectives Include: Boiler Diagram; Types of Boiler. #1. Fire Tube Boilers. Wet Back Design ...

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam.. The fire-tube boiler developed as the third of the four major historical types of boilers: low-pressure tank ...

BURNHAM COMMERCIAL FIRETUBE BOILERS Burner/boiler systems produce steam or hot water in a .. SCHEMATIC TANKLESS HEATER PIPING. In newer systems, the diaphragm expansion tank may be attached to the boiler piping near the boiler. The expansion tank must be properly. As drawn in the diagram, to charge the tank from the primary loop.

Fire-tube boiler: Fire-tube boiler is those boiler in which the fire or hot gas is present inside the tubes and water surrounds these fire tubes. Since fire is inside the tubes and hence it is named as fire tube boiler. The heat from the hot gases is conducted through the walls of the tube to the water.

Fire-Tube Boiler (~1800) The fire tube boiler, the oldest design, is made so the products of combustion pass through tubes surrounded by water in a shell. The furnace/flame volume can either be inside or external to the shell that contains the water. The upper steam capacity of fire tube boilers is about 20,000 Ibm/hr, and the peak pressure

Fire tube boilers pass fire and hot combustion gas through the interior of the boiler tubes to heat the water that surrounds the tubes (see Figure 1.1). This type of boiler design is commonly used for factory-assembled (package) boilers, which are low pressure.

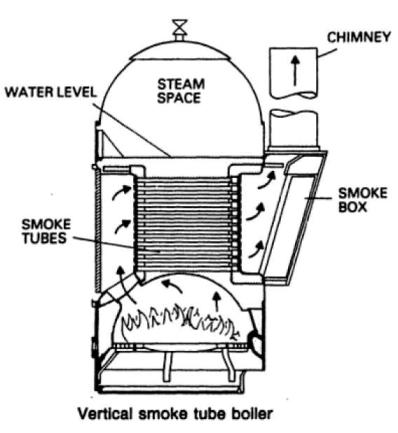

7. 5. Vertical fire-tube boiler It is the simplest fire tube boiler which consists of a cylindrical shell containing greater portion of water and remaining portion is occupied by steam. It contains cross tubes and a furnace at the bottom of the boiler. The combustion gases after heating the water are allowed to escape into atmosphere. 8.

Fire Tube boiler is the simplest form of the internal furnace, vertical fire tube boiler.Fire tube boilers are a portable boiler and it requires a small floor space. The steam rating in fire tube boilers doesn't exceed 2500 kg per hour and pressure is limited to 10 bars.

The combustion chamber is located in an integral part of the boiler, so this is also an Internally fired boiler. The steam produced by these boilers has a pressure of about 10 bar (max. range up to 15 bar), so they are called low-pressure boilers. Diagram of a Fire-tube Boiler

In water tube boilers the water travels inside the tubes and the heat on the outside, as shown in the video above. Cast iron boilers are similar to water tube boilers, but the water is contained in cast iron sections instead of in tubes. The diagram below shows the components of a fire tube boiler. Fire Tube Boiler Diagram

Water Tube Boiler Components. Here is a review of the water tube boiler parts and functions.. Boiler Shell: This shell is the external cylindrical part of a pressure container. Steam drum: It is a collection vessel for steam and water. Mud drum: This is a cylindrical formed space at the base of the water space. It will gather impurities like mud, sediment, and others.

Fluids Free Full Text Three Steps Mixed Fire Tube Water Tube Vertical Boiler To Optimize Thermal Performance

Sl No.: Fire Tube Boiler: Water Tube Boiler: 1. The Hot flue gases flow inside the tube and water has surrounded the tube.: The water flow inside the tube and the hot flue gases have surrounded the tube.: 2. This is heavy in weight.: This is light in weight.: 3. This is also called as internally fire tube boiler and: This one is called an Externally Fire-tube boiler.: 4. ...

Locomotive boiler is a boiler type that is used to heat up the water and create steam from this water. This boiler sits horizontally, just like Lancashire boiler and Cornish boiler. Many people think that Locomotive boiler is a water tube boiler, but in fact, it's a fire-tube boiler.

Fire tube boilers have been used throughout the world for over a century and have been …. Figure 1: Schematic diagram of two pass packaged fire tube boiler. 1 …. Lancashire Boiler Construction,working,Diagram Jan 7, 2015 …. Lancashire Boiler - Lancashire Boiler is a stationary,fire tube,internally fired, horizontal and natural ...

Download scientific diagram | 0 Fire tube boilers from publication: Study on the thermodynamics performance of industrial boiler | Boilers are prime source ...

Fire Tube Boiler Disadvantages: The following disadvantages of fire tube boiler are: The fluctuation of load cannot be easily handled. The rate of steam generation is low. A Fire boiler is used in small power plants. The maximum working pressure is up to 20 bar which is a less comparatively water tube boiler. Overall efficiency is up to 75% only.

Schematic Diagram Of Fire Tube Boiler. Water tube boilers are those boilers in which water flows through a number of tubes called water tubes and the hot gases produced by the combustion of fuel in the boiler furnace while on their way to chimney pass surrounding the tubes. A slightly more successful adoption was the use of hybrid water tube ...

Fire tube boiler is one of the most basic types of boiler and the design is also very old. It was popular in 18 th century. It was mainly used for steam locomotive engines. Operation of Fire Tube Boiler. Operation of fire tube boiler is as simple as its construction. In fire tube boiler, the fuel is burnt inside a furnace.The hot gases produced in the furnace then passes through the fire tubes.

The shell of this type of boiler is arranged in the vertical direction that has multi tubes. These multi tubes arranged in vertical and the high ...

750-94 (revised 2009) Model CB, CB-LE Packaged Boiler Manual i Model CB, CB-LE Packaged Boiler 750-94 Table of Contents CHAPTER 1 Basics of Firetube Operation 1-1 1.1 — Introduction 1-1 1.2 — The Boiler 1-4 1.3 — Construction 1-5 1.4 — Steam Controls (All Fuels) 1-6 1.4.1 — Operating Limit Pressure Control 1-6 1.4.2 — High Limit Pressure Control 1-7 1.4.3 — Modulating Pressure ...

Comments

Post a Comment